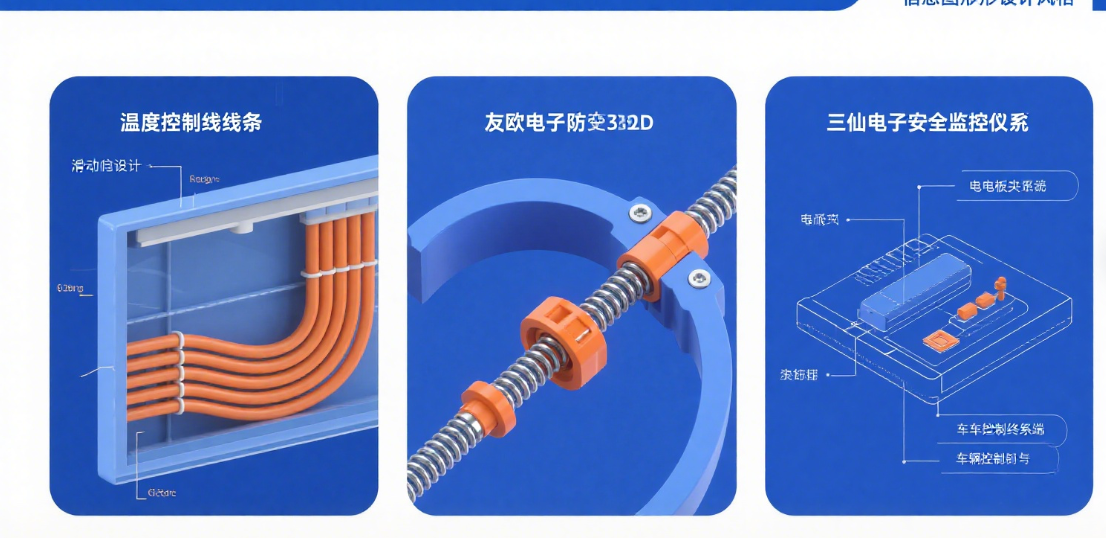

In the past week, the wiring harness industry has seen a surge in patent activity. Several companies have announced their innovative achievements: A new type of temperature control system wiring harness uses a sliding harness compartment design to unify and organize flat and round wiring harnesses, significantly improving the neatness of internal structures and enhancing the efficiency of later maintenance.

Youou Electronics has developed an anti-crossing device that effectively prevents the entanglement of automotive signal communication wiring harnesses through the coordinated action of curved grooves and spring-loaded telescopic rods, ensuring stable signal transmission.

More notably, Sanxian Electronics has introduced a safety monitoring wiring harness system. This system integrates a voltage sensor into the conductive plate clamping structure, enabling real-time monitoring of current transmission status. In case of any anomalies, it immediately alerts the vehicle's control terminal. This provides a novel solution for addressing the safety hazards associated with current transmission in electric vehicles.

02Market Expansion, Driven by New Energy to Boost Both Volume and Value

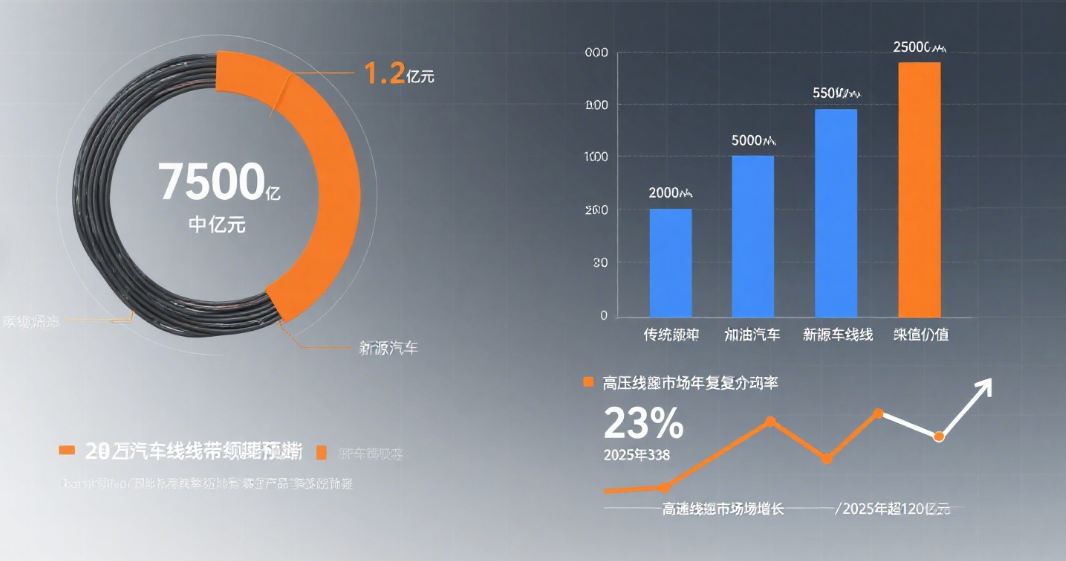

The industry transformation is strongly driven by the new energy vehicle (NEV) market. According to industry analysis, the size of China's

Automotive Wiring Harness market is expected to exceed 1200 billion yuan by 2025, with NEV wiring harnesses accounting for 750 billion yuan. Compared to traditional internal combustion engine (ICE) vehicles, the value of NEV wiring harnesses has significantly increased. The price range for wiring harnesses in traditional ICE vehicles is between 2500 and 5000 yuan, while NEVs, due to the addition of high-voltage wiring systems, have an average price of around 5000 yuan.

The high-voltage wiring harness market is expanding at an annual compound growth rate of approximately 28%, and it is projected that the domestic market size will reach 23.8 billion yuan by 2025. Meanwhile, the demand for high-speed wiring harnesses is also surging in tandem with the advancement of vehicle intelligence, with the market size expected to exceed 12 billion yuan by 2025.

03 The Three Trends Reshaping the Technical Logic of the Industry

The current evolution of the wire harness industry is characterized by three main technological threads:

1. **Lightweighting as a Top Priority:** Traditional automotive wire harnesses weigh between 50-70 kilograms, accounting for about 5% of the total vehicle weight, making them the third heaviest component after the engine and chassis. The industry is achieving weight reduction through thin-walled wires, cross-sectional optimization, and the substitution of aluminum for copper. Some aluminum connectors have already achieved a 40% weight reduction compared to traditional copper materials, with costs simultaneously decreasing by 25%.

2. Centralization of Electronic and Electrical Architecture (EEA) is Revolutionizing Design Concepts: Tesla has optimized its EEA architecture, reducing the wire harness length in the Model 3 to 1.9 kilometers, a 37% decrease from the 3 kilometers in the Model S. Aptiv's Smart Vehicle Architecture (SVA) integrates multiple ECUs into domain controllers, reducing wire harness weight by 20% and laying the groundwork for automated production.

3. Automation in Production Overcoming Labor-Intensive Bottlenecks: Currently, approximately 95% of wire harnesses rely on manual production, with labor costs limiting capacity expansion. Leading companies are pushing for automation across the entire process, including wire cutting, crimping, and insertion, significantly improving efficiency and reducing dependence on human labor.