As global manufacturing transitions towards digitalization, intelligence, and green initiatives, wire harnesses, which are referred to as the "blood vessels" and "nerves" of industrial systems, are quietly becoming a core driving force in this transformation.

In 2025, the wire harness industry will experience a new round of growth driven by strong demand in multiple application fields such as new energy vehicles, industrial automation, and 5G communications. According to the latest data, the demand for the wire harness industry in China is expected to reach 2.3135 million tons in 2025, representing a year-on-year increase of 3.3%. High-voltage, lightweight, and intelligent solutions are becoming the core trends in the industry, while environmental protection and sustainable development are critical issues that the industry must address.

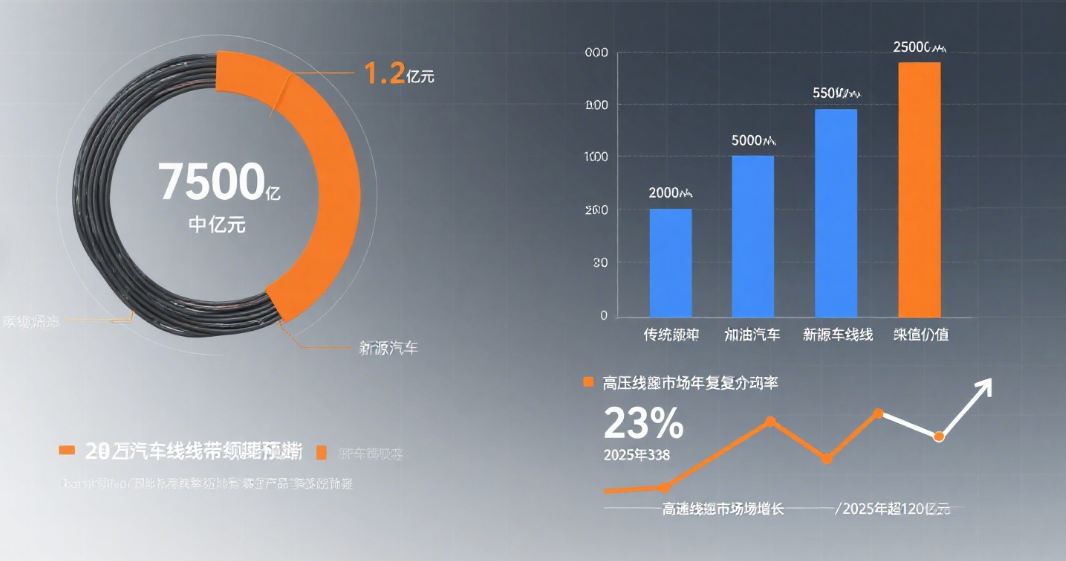

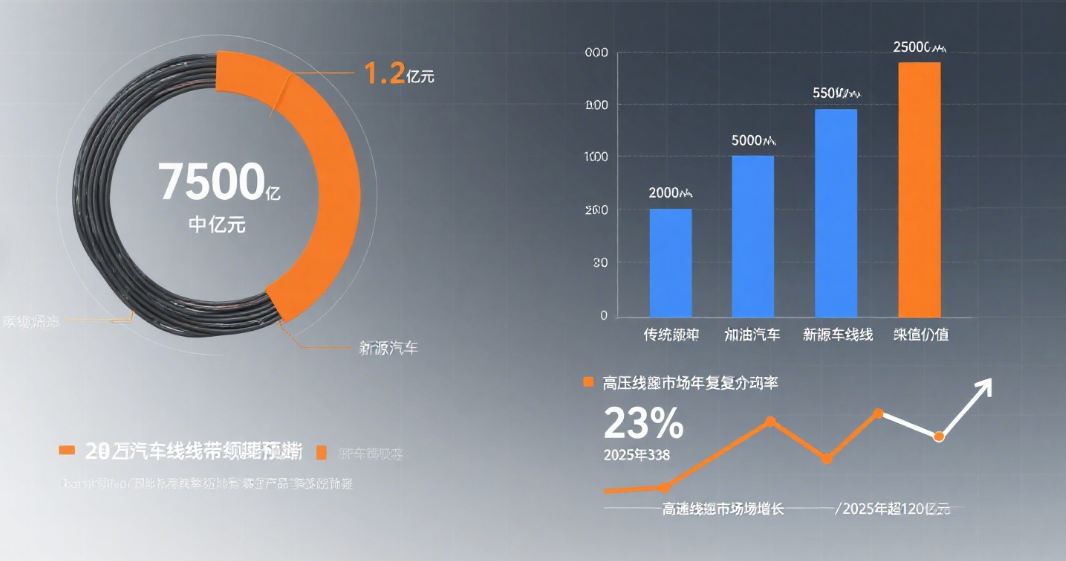

01 The industry scale is steadily growing, with new energy vehicles becoming the main driving force. As a component that connects various electrical devices in a circuit, wire harnesses consist of fine components such as wires, terminals, connectors, and sheaths, achieving the connection, transmission, and separation of electrical signals through connectors and wiring. It is not only the "nervous system" of China's automotive industry but also an indispensable key component in multiple fields, including industrial equipment, communication equipment, and medical devices. In 2023, the market size of wire harnesses in China has reached approximately 326.8 billion yuan, with a year-on-year growth of 7.3%. It is projected that by 2025, the Chinese automotive wire harness market will reach a scale of 120 billion yuan, with new energy vehicle (NEV) wire harnesses accounting for as high as 62.5% of the total. The demand for wire harnesses in NEVs far exceeds that of traditional internal combustion engine vehicles, with the value of wire harnesses per vehicle increasing by 30%-50% compared to traditional fuel vehicles. The continuous growth in demand for high-voltage wire harnesses and battery management system wire harnesses is driving the market towards the development of lighter, more highly integrated products.

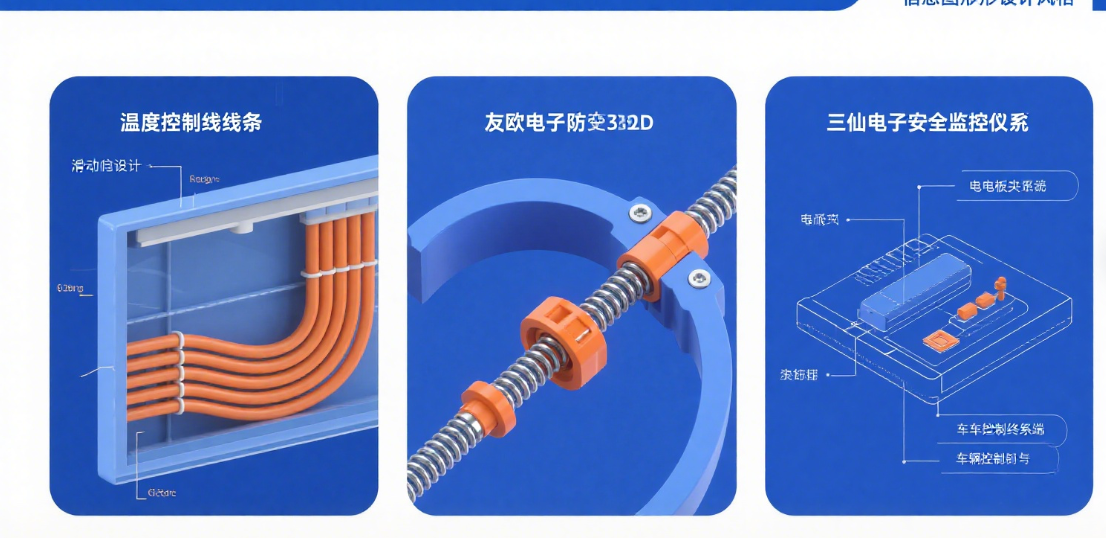

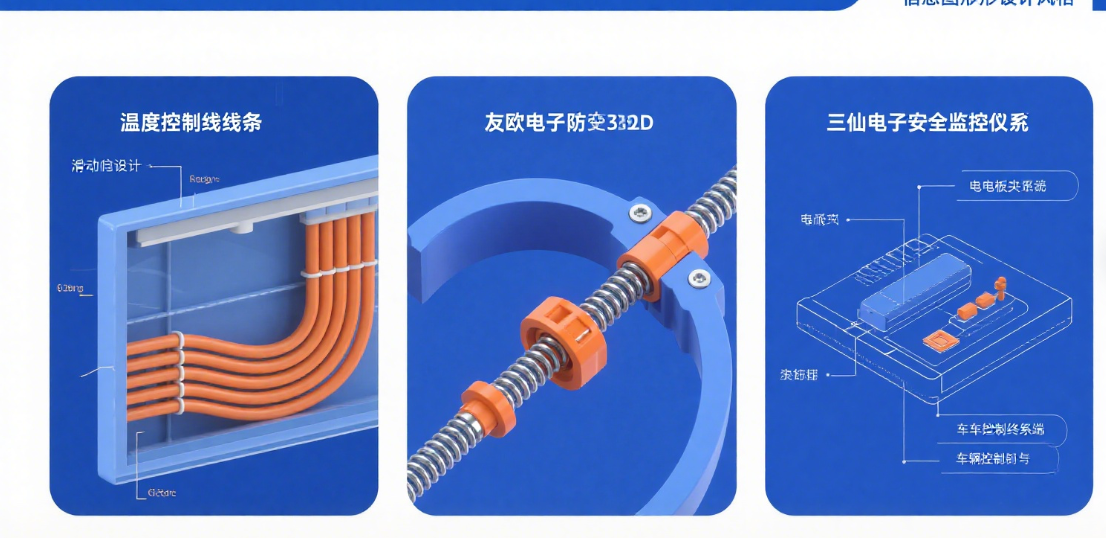

02Three Major Trends in Technological Development: High Voltage, Lightweight, and Intelligence

As 800V high-voltage platforms become more prevalent in the new energy vehicle sector, the demand for high-voltage wiring harnesses has surged. In 2023, the global market size for automotive high-voltage wiring harnesses reached 39.7 billion yuan, and it is projected to grow to 48.4 billion yuan in 2024 and 99.8 billion yuan by 2030, with a compound annual growth rate (CAGR) of 14.1% during this period.

Lightweighting is a critical initiative for the wiring harness industry in response to energy crises and environmental requirements. By replacing traditional copper wires with aluminum alloy conductors, weight can be reduced by approximately 25-30%. Additionally, optimizing the design of wiring harness structures and eliminating unnecessary components and redundant wiring can also help achieve lightweighting goals.

The transition towards intelligence is accelerating in the wiring harness industry. In production, the introduction of automated equipment, robots, and artificial intelligence technologies significantly enhances production efficiency and quality consistency. Wiring harness companies that implement MES (Manufacturing Execution System) can improve their yield rate to 99.97%.

03The upgrade of intelligent manufacturing equipment has significantly improved automation rates in the wire harness intelligent manufacturing equipment industry in recent years. The adoption rate of fully automatic crimping equipment has increased from 35% in 2020 to 60% in 2025, while the proportion of labor costs has decreased from 25% to 12%.

In 2024, the global shipment of wire harness equipment is expected to reach approximately 240,000 units, with about 125,000 units being intelligent manufacturing equipment for wire harnesses. It is projected that this number will continue to grow in 2025.

The market penetration of domestically produced equipment in the automotive wire harness intelligent manufacturing equipment market has risen from 25% in 2023 to over 35% in 2024. With the widespread adoption of 800V high-voltage platforms and the expansion into overseas markets, domestically produced equipment is entering a period of rapid growth.